The Slush Plus Difference

When looking for a reliable frozen cocktail, shake, slushy, or soft serve machine, you want to be sure you are only buying quality equipment that will last years of dependable service.

Save up to 80% off retail with our certified refurbished machines.

All refurbished machines are refurbished in-house by our dedicated team.

Technical support or general assistance is only a phone call way - speak to a real person immediately.

We only sell equipment from reliable, dependable brands with decades of manufacturing experience and solid warranties.

New Equipment

With so many different brands out there to choose from, it can be confusing on which frozen drink machines to buy to serve your thirsty customers. With years of experience, we only stock brands that we trust and know make reliable equipment. All of the new machines we carry come from reputable, trusted brands that make equipment built to last - with solid warranties, real technical support, and easy parts and service availability.

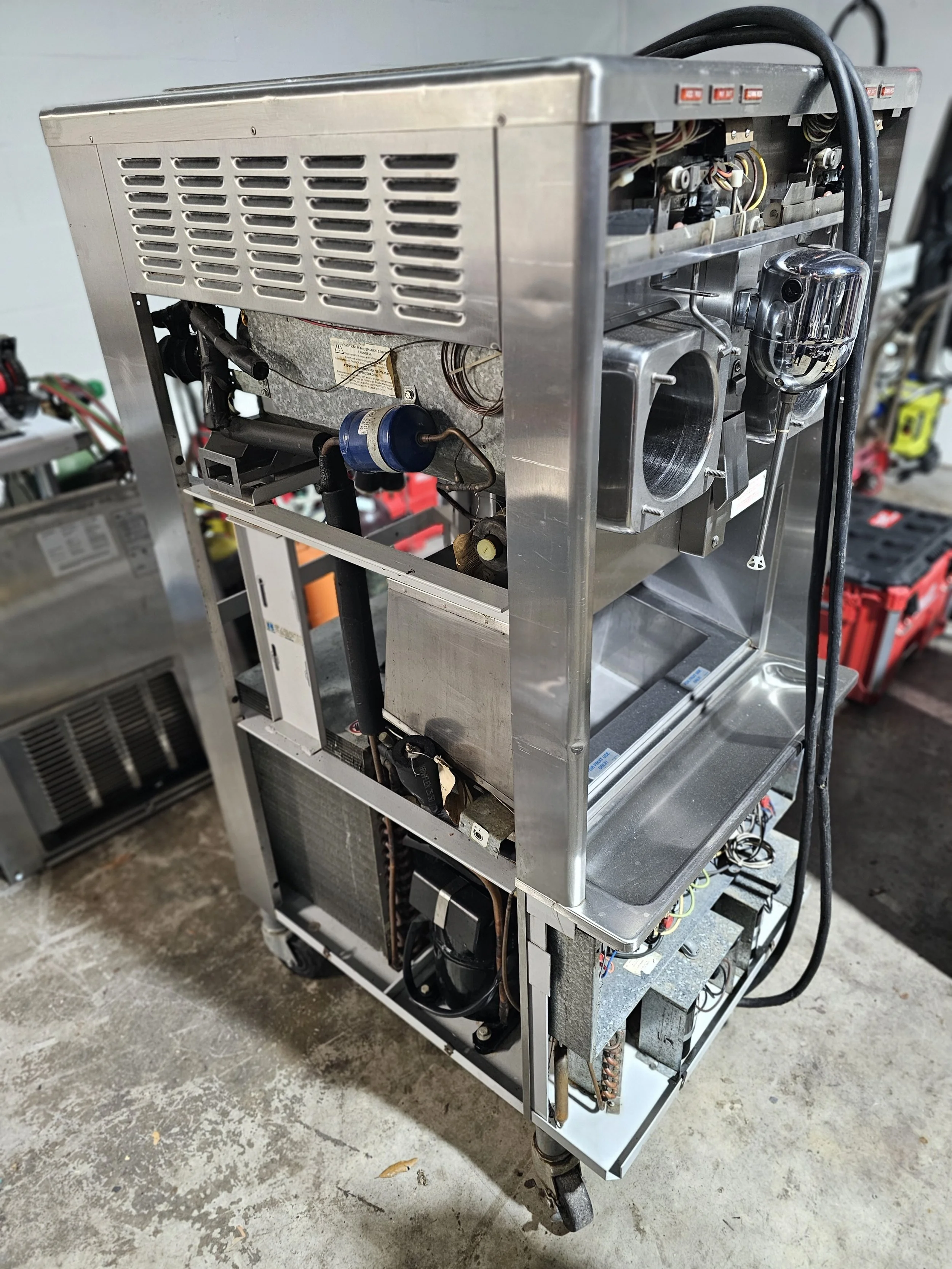

Refurbished Equipment

Every refurbished machine we sell comes with a 30-day parts and labor warranty, along with a 90-day compressor warranty, giving you immediate confidence in your purchase at a cost-effective price-point. For added protection, we offer 1-year extended full parts warranties on select equipment. We stand behind our refurbishment process and are proud to offer the best warranties in the industry. All of our equipment goes through our rigorous, in-depth process before it is securely packed and shipped out to you.

Our In-Depth Refurbishment Process

-

Exterior Cleaning

All stainless steel panels are deep cleaned. Any heavily damaged panels are replaced. Exterior lids, drip trays, or plastic accessories are replaced if missing or damaged. Casters and legs are cleaned and replaced if needed.

-

Usability & Electrical

LED indicator lights, touchscreens, switches, buttons, etc. are tested and repaired or replaced. Power cords are checked for damage and repaired or replaced.

-

Interior Cleaning

Entire machine is stripped down and deep cleaned through our proprietary process. Frame and interior metal surfaces are painted with rust-preventing paint. All electrical connections, contactors, motors, fans, control boards, and mechanical assemblies are tested, repaired, and deep cleaned.

-

Compressor Check

Compressor current draw, pressures, and full operation checked. Acid test completed and acid treatment performed if needed. Capacitors tested and replaced if out of range or damaged.

-

Refrigeration System

Proper cylinder and hopper cooling checked, repaired as needed. Capillary tubes checked and replaced. EPR and TXV valve pressures adjusted to within manufacturer spec. Condenser deep cleaned, cooling fan tested.

-

Drive System

Drive motors tested, capacitors tested. Drive belts replaced, gearbox assemblies tested, oil and bearings replaced. Drive shafts, pullies, and belts aligned.

-

Cylinder Assembly

Faceplates inspected for damage, replaced if cracked. Beater assembly and all cylinder assembly parts checked and repaired or replaced as needed. New o-rings, blades, and wearable plastic parts replaced. Draw valve and handles checked and replaced.

-

Calibration

Temperatures and viscosity settings checked and calibrated. Testing of all indicators, sensors, and machine parameters.

-

Functionality Testing

Final testing of all operations. Test temperatures, draw operations, cycle times and cut-in/out parameters. Compressor and drive motor performance testing.

-

Real-World Testing

Machine is loaded with mix and tested under real-world use conditions. Machine is ran non-stop for a minimum of 72 hours. Final check for leaks, freezing performance, and proper mix dispensing. Once complete, final cleaning and packing for shipment.